Services

Advanced materials

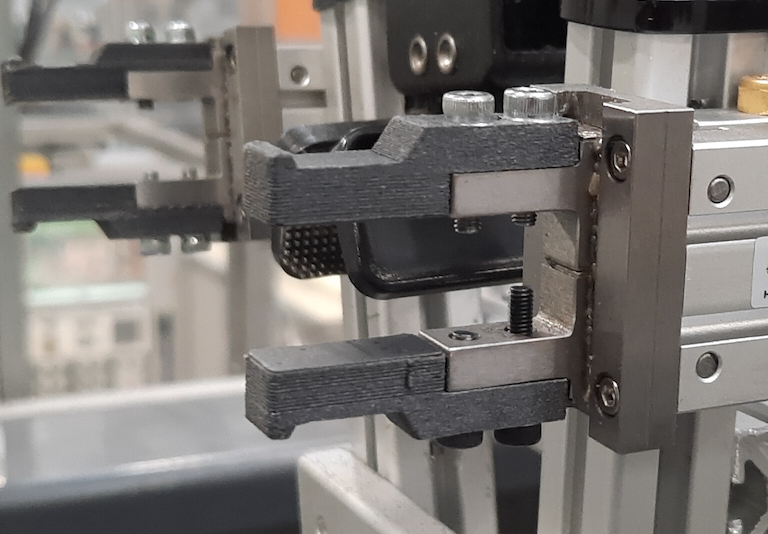

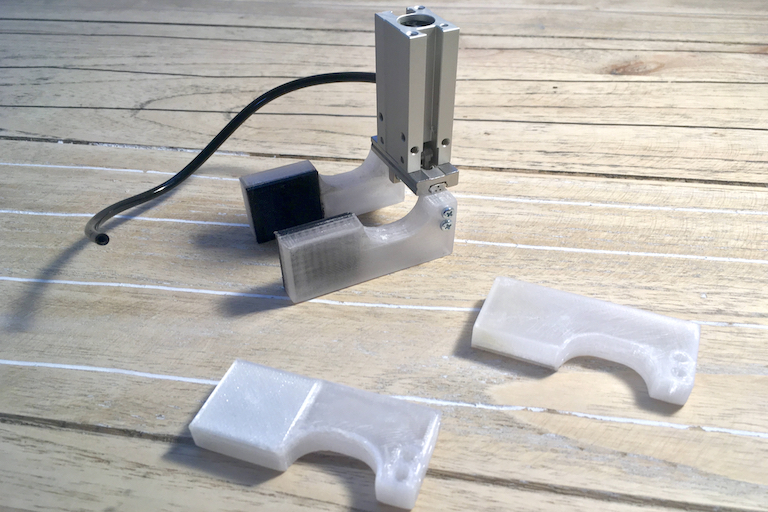

Do you need strong production tools or manufacturing aids? Are you looking for handling fixtures for an automated robots capable withstanding high temperatures and pressure combined with a flexible material? Thus handling the final production with care. Combined or composite materials will do the job.

Investment patterns

Are you struggling to cut costs of investment patterns for metal casting? Eliminate the costly and time consuming tooling process including wax patterns and replace it by a polished 3D printed pattern.

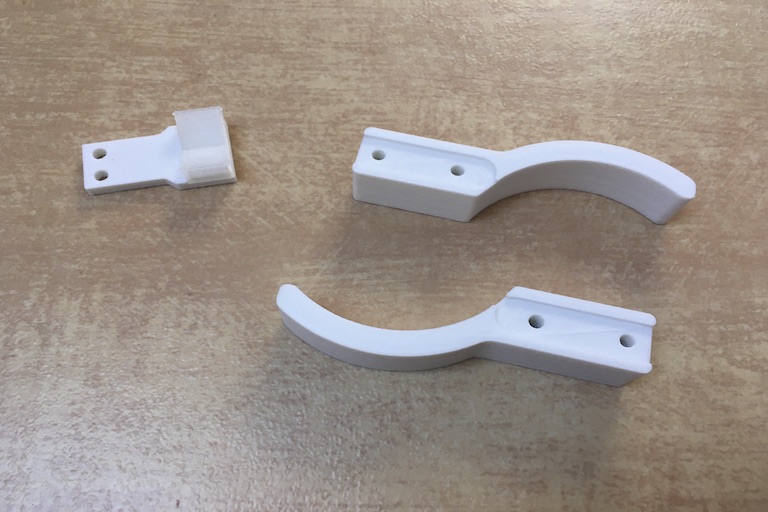

Checking fixtures

Are you seeking an alternative to CNC jigs and checking fixtures? Have them 3D printed and save the time and money for your own production.

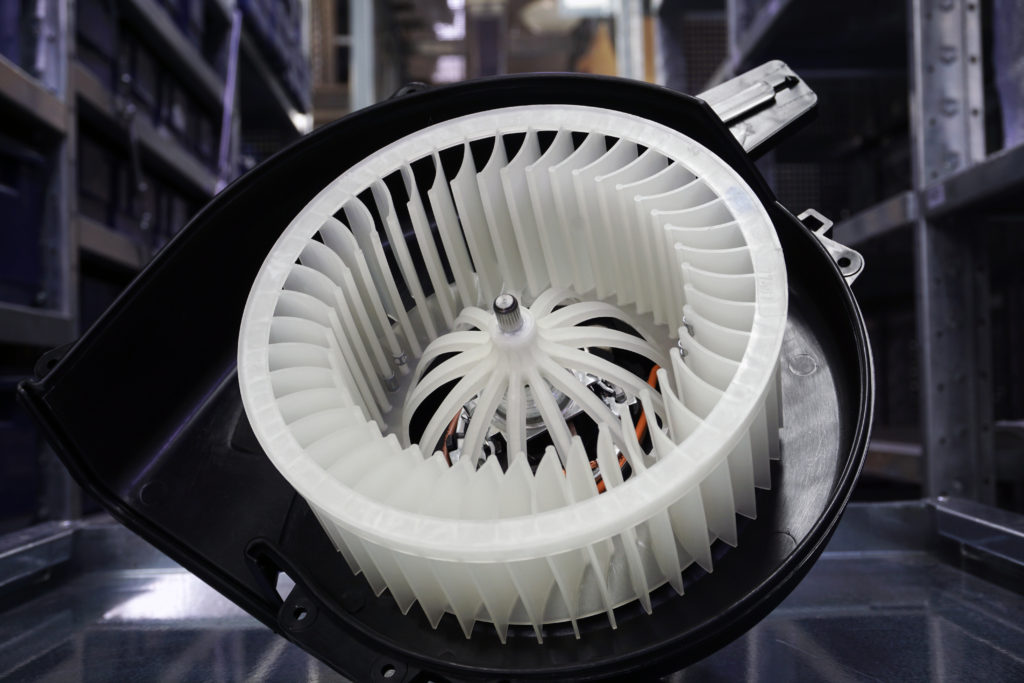

Spare parts

Are you looking for a scarce expensive spare part or a spare part with a longer service life and specific properties? We will design and manufacture the spare part from a corresponding material according to your needs.

Models and prototypes

Would you like to present a product model, architectural study or a significant building? Have them 3D printed and save your time and money.

Specific requests

Are you looking for and need to test a special material? We will print for you the required prototype for physical or chemical tests according to the predefined requirements.

Technology

FFF

SLS

LFS

Our FFF additive manufacturing is built upon the Ultimaker industrial printers. Printers are renowned for industrial quality of prints popular among professionals across industries. Many designers, architects, health professionals, artists or modelers benefit from capabilities of the Ultimaker printers. Devices have build volume of 330 x 240 x 300 mm. Larger pieces are joined with locks or glued.

Sintering of polymer powders represents a very precise production technology. Thanks to the elimination of temporary supports, it is possible to print very complex and fully functional mechanical parts or waterproof components in a quality comparable to conventional production methods. Our SLS additive manufacturing is build upon the Formlabs FUSE1 device with a print volume of 165 x 165 x 300 mm.

Produce functional, high-quality prototypes and end-use parts in short time. Our Form 3+ LFS printer consistently delivers an affordable, waterproof industrial-quality professional 3D prints from a wide range of high performance materials. LFS technology is trusted by tens of thousands of professionals around the world, whether needed for rugged performance parts or accurate details. Form 3+ available print volume is 145 x 145 x 185 mm.

Ultimaker filaments are commonly used for the production of visual prototypes, production tools and functional parts with a requirement for specific durability. The basic family of materials includes: PLA, TPLA, ABS, PETG, PA, CPE / +, PC, PP, TPU. However, thanks to the third-party support, printers have a wide range of additional materials available consisting of more than 200 representatives. These include specialty elastomers, composites (CF/GF), ESD certified materials, biocompatibles, resistant to UV radiation, weather or harsh chemicals and high temperatures.

Formlabs polymer powders enable production of very strong and precise parts. PA12 material is designed for general use with a high transfer of details and dimensions. Especially designed for the production of permanent jigs, clamps or tools and high-performance prototyping. In contrast, PA11 is a tough, flexible material for functional parts with high impact resistance. This material can be used to produce thin-walled cases and channels, latches, clamps, hinges or aids for orthotics and prosthetics.

LFS technology is ideal for rapid prototyping and production, rapid tooling and manufacturing aids, patterns for molds and casting or model making. Rich material library includes advanced resins for industry quality parts and specific standards (ESD, FR, Rigid, High Temp, Technical Ceramic), engineering materials comparable resins (ABS, PP, PE, PEEK), flexible and elastic resins (ShA 50, ShA 80, Silicone ShA 40, Polyurethane) or robust, functional, and dynamic materials that can handle compression and impact without breaking.

3D SKILL Studio

Ing. Josef Tyrpák, MSc., Ph.D.

Bitozeves 47

440 01 Louny

CZECH REPUBLIC